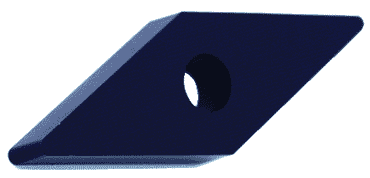

VNGA 332 Grade PCA2 - Turning Insert

Pricing Notice

Due to evolving trade policies, product prices may be subject to change. For details, please refer to our Terms of Sale. We remain committed to offering competitive pricing and exceptional service.

Terms of SaleHave a Question About a Product?

Our team is here to answer all your questions and provide the detailed information and support you need to make product decisions.

Contact UsVNGA 332 Grade PCA2 - Turning Insert

ManufacturerProCut

Part #FF5510610

MFG #FF5510610

VNGA 332 Grade PCA2 - Turning Insert

$14.49

/ EAKnowledgeable Product TeamBenefit from our experienced team, ready to assist you with expert product knowledge and ensure a seamless shopping experience.

- Manufacturer Name: ProCutANSI Number: VNGA 332Grade: PCA2IC: 3/8Radius: .031Thickness: .187

-

- Ceramic Inserts for Hi-Speed Machine Applications

- Application DataUse the strongest shape and largest nose radius possible. Round and square inserts should be used whenever possible since they are stronger than diamonds and triangles. For heavier cuts, 5/16″ thick inserts are recommended. Use the largest lead angle possible. Use the largest side cutting edge that the shape of the workpiece allows. As the side cutting angle is increased, the length of the cutting edge that contracts the workpiece is increased and the load is distributed over a greater area of the cutting edge. Use proper edge preparation techniques. Proper edge factors in successfully applying ceramics over a wide range of materials and applications.

- PCA–2 is Hot Pressed Black CeramicRoughing and finishing of hardened steel and chilled cast irons, and for machining cast irons with sandcast scale. Also clean irons or steel of hardness below 425 BHP or about Rockwell C–45.

- Manufacturer Name: ProCutANSI Number: VNGA 332Grade: PCA2IC: 3/8Radius: .031Thickness: .187

-

- Ceramic Inserts for Hi-Speed Machine Applications

- Application DataUse the strongest shape and largest nose radius possible. Round and square inserts should be used whenever possible since they are stronger than diamonds and triangles. For heavier cuts, 5/16″ thick inserts are recommended. Use the largest lead angle possible. Use the largest side cutting edge that the shape of the workpiece allows. As the side cutting angle is increased, the length of the cutting edge that contracts the workpiece is increased and the load is distributed over a greater area of the cutting edge. Use proper edge preparation techniques. Proper edge factors in successfully applying ceramics over a wide range of materials and applications.

- PCA–2 is Hot Pressed Black CeramicRoughing and finishing of hardened steel and chilled cast irons, and for machining cast irons with sandcast scale. Also clean irons or steel of hardness below 425 BHP or about Rockwell C–45.

Pricing Notice

Due to evolving trade policies, product prices may be subject to change. For details, please refer to our Terms of Sale. We remain committed to offering competitive pricing and exceptional service.

Terms of SaleHave a Question About a Product?

Our team is here to answer all your questions and provide the detailed information and support you need to make product decisions.

Contact Us$14.49

/ EA